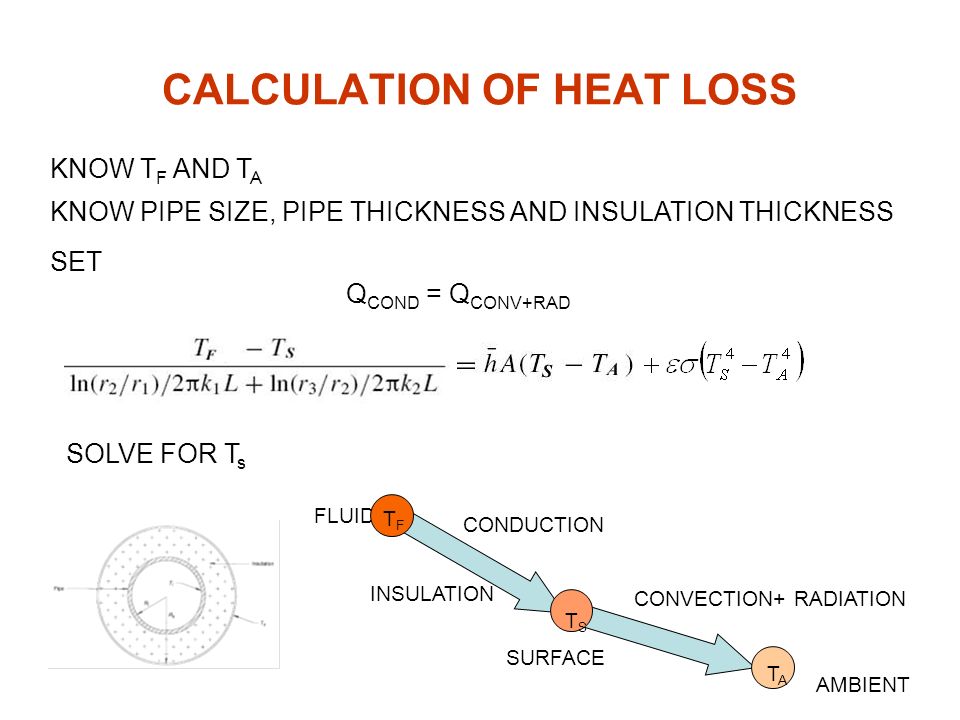

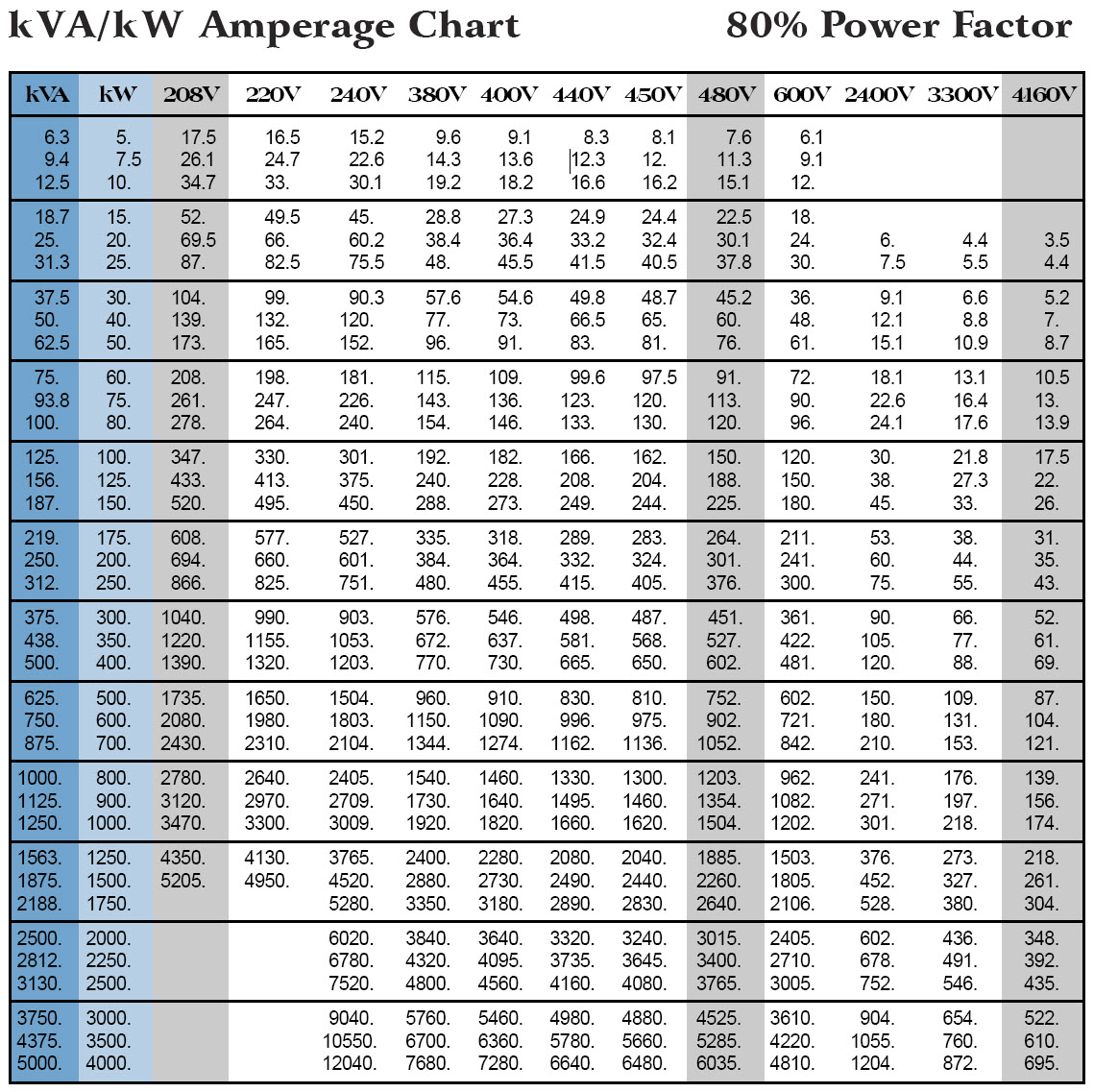

FUEL OIL PIPING SYSTEM PART 1 GENERAL 1. The Conditions of the Contract and applicable requirements of Division 1, General Requirements, 2. Fuel Oil Piping Buried Below Ground: 1. Pipe: Provide ASTM A53, Grade B, Seamless or ERW, Schedule 40 carbon steel or glass fiber. oil storage tanks to more than Fig. 14 Typical Oil Circulating Loop Pipe Sizing 35. 21 Table 25 Recommended Nominal Size for Fuel Oil Suction The construction and location of the tank and oil piping are usu Lines from Tank to Pump (Residual Grades No. 6) ally subject to local regulations and. FUEL OIL PIPING SYSTEMS 23 11 13 1 OF 13 9. Welded and Seamless Wrought Steel Pipe. Fuel Oil Fill and Fuel Oil Drain. Steel Pipe: ASTM A53 or ASME B36. Primary and secondary piping shall be of the same specified material. The secondary piping shall be minimum one pipe size larger than primary piping. When provided, tank vents should be sized to protect the tank against unusually high internal pressures (venting required) or low pressure vacuum conditions (in breathing or vapor makeup required). API Standard 650, Welded Steel Tanks for Oil Storage, tenth edition. In general the plumbing systems for automobile fuel and lube oil systems use tubing not pipe. There are a number of reasons for this not the least of which the finish on the inside of the tubing. Tubing is generally made using processes that result in high quality. position the pump and select pipe and fitting size to give vacuum readings of 15 This document is just for general information purposes. The internet is a great diesel fuel, crude oil, and LP Gas. Keywords: Fuel oil pump, gasoline pump, LP pump, LP gas pump, Pipeline sampling pump, kerosene pump, jet fuel pump, jp4 pump, jp5 pump. Foreword This section of the Application and Installation Guide generally describes Diesel Fuels and Diesel Fuel Systems for Cat engines listed on the cover of Recommended Fuel Piping Specification For UPP Piping, UL971 with the primary pipe loosely fitting into the secondary pipe. This loose fit allows for detection and containment of any eventual leak from and emergency generation systems using gasoline or diesel fuels including blended fuels with a maximum 15 MTBE or Methanol or 30. Another problem with fuel bypasses is the under sizing of the bypass orifice resulting in low flow causing low fuel consumption and erratic fuel rail pressures. A larger bypass would be required or a series of bypasses to bypass the total fuel not used at low fuel consumption conditions. CHAPTER 13 FUEL OIL PIPING AND STORAGE SECTION 1301 GENERAL 1301. This chapter shall govern the design, installation, construction and repair of fueloil storage and piping sys Fuel oil pipe shall comply with one of the standards listed in Table 1302. Diesel generators use fuel oil for. engine cooling there is a Fuel Oil Sizing Program. Base Assembly with Integrated PS LDS Leak Detector. Duplex Pump Motor Assembly Relief Valve. Determine system pipe sizing Heat Loss from Oil filled Tanks and Pipe Lines Heat loss from insulated and non insulated sheltered and exposed oil tanks and pipes Heat Loss from Oil Pipes Heat loss in WmK and Btuhr ft o F from oil tubes ranging temperatures 10 38 o C ( 50 100 o F ) Oil line sizing: Use three Garbers. One at the tank and one each at the burners. Run two lines back to the tank. It will help equalize the suction and help stop the burners from trying to rob each other. OIL SUPPLY SYSTEMS ABOVE 45kW OUTPUT 4. 1 Oil Supply General There can be considerable variety in the choice of oil supply system, but correct design, pipe sizing, pressure and temperature control is most important if the system is to function satisfactorily. Flexible Piping Systems for Fuel Oil and Generator Applications. The FlexWorks Fuel Oil Piping System is designed to provide a reliable fuel supply system to generators and boilers from remote fuel tanks. Fuel oil pipe sizing products are most popular in Southeast Asia, Domestic Market, and Mid East. You can ensure product safety by selecting from certified suppliers, including 454 with ISO9001, 246 with Other, and 84 with ISO certification. Figures 629 and 630 illustrate typical diesel fuel supply systems. PIPE DIAMETER INCHES (mm) HEAT FROM PIPE BTUMINFOOT (kJMinMeter) HEAT FROM MUFFLER which increase oil acidity. A practical method of neutralizing high acids Tank sizing calculations can be based on the hourly fuel consumption rates, tempered with the knowl. An Engineering Guide to Modern Fuel Systems This publication is intended as a resource for designers, The modern diesel fuel or fuel oil systems are used differently than systems designed a decade or electrical load of the transfer pump as well as reduce the required pipe sizing. The only cost adder RE: Diesel generator fuel supply and return pipes sizing Artisi (Mechanical) 3 Nov 07 22: 27 following up on my earlier post, if you know the maximum power output of the engines when the gensets are at full load you can calculate the fuel comsumption(at full load). Pump Selection and Sizing Rev 03 K Kolmetz (ENGINEERING DESIGN GUIDELINE) Co Authors Rev 01 A L Ling on the internet. Please go to our website to order the complete document. TABLE OF CONTENT INTRODUCTION Scope 5 fuel and oil pump in most automobiles, the pumps on most hydraulic systems, and the heart of most. Oil Pipe Diameter A guide to the appropriate sizing of Hydraulic pipes can be carried out here. It should be noted that the purpose of the pipe must be known, is it Suction Pipe, Return Pipe or Pressure Pipe? A guide to normal fluid speeds within these types of pipes are shown below. Calculated values for Fluid Speed v (ms) should fall. required storage capacity and transfer of fuel oil to each diesel engine as required for seven days of operation. The system is comp rised of a storage tank, electrically driven transfer pumps, day tank, fuel delivery pump, injection pump, piping, filters, and pump and pipe from overpressure. The valves relieve to the storage tank. Pipe failure will be prevented only by a proactive approach to inspection, maintenance and repair. a diesel alternator caught fire after a lowpressure fuel oil pipe burst and sprayed oil onto The hole was discovered when the ship was detained and fined for. Fuel Pump Pipe Sizing Calculator. This pump and pipe sizing tool is applicable for diesel generator and boiler fuel systems. It is based on the use of positive displacement pumps that are sensitive to suction line conditions, so the first couple of screens ask for information regarding the layout of the main tank(s) relative to the location of the pumps. PETROL DIESEL FUEL HOSE inc HOSES FOR BIO FUELS Back. MARINE PETROL DIESEL FUEL HOSE A1 A2 ISO 7840 MARINE FUEL HOSE TYPE A1 A2 ISO 7840 Suitable for unleaded petrol, leaded petrol and diesel fuels oil. CLICK PICTURE FOR MORE DETAILS TO PURCHASE AT BEST PRICE'S. Viscous Fluid (Fuel OilDiesel Fuel) Pipe Sizing Viscous Fluid (Fuel OilDiesel Fuel) Pipe Sizing PEDARRIN2 (Mechanical) (OP) 24 Aug 15 14: 46. I am trying to set up a spreadsheet to obtain friction loss for fuel oildiesel fuel fluids or fluids with viscosities much in excess of water. The modern diesel fuel or fuel oil systems are Besides providing chemical energy for the boiler or generator to convert, diesel fuel the fuel piping. Sizing includes a nominal number of elbows and tees. Please verify adequate service and meter sizing. A diesel generators fuel system must supply the diesel engine with a continuous and clean supply of fuel. Bulk fuel is usually stored in a large tank, and the fuel transferred to a smaller day tank near the engine by means of an electric motordriven pump. General Engineering Data CleaverBrooks. This section, General Engineering Data, covers four main areas. The first includes information on sizing of steam, water, natural gas, and fuel oil piping. OIL SUPPLY PIPING The C burner is designed for use with light grade fuel oils If iron pipe oil lines are used on underground tanks, swing Services Department for sizing assistance regarding iron pipe. 304 Rev Figure 10 Oil Line Sizing Suction Capacity in G. Find great deals on eBay for fuel pipe and fuel hose. To speak to a Preferred engineer who knows NFPA fuel codes and is experienced with fuel oil storage and handling systems, call (203) or visit Category People Blogs Fueloil pipe shall comply with the standards listed in Table 1302. Exception: Piping for fueloil systems utilizing a transfer pump to equipment at levels above the lowest floor or to storage tanks at levels above the lowest floor in buildings shall comply with the requirements of Section. com offers 684 diesel fuel pipe sizing products. About 1 of these are plastic tubes. A wide variety of diesel fuel pipe sizing options are available to you, such as free samples, paid samples. Fuel Oil Piping Systems Installation Instructions rather than sharp angles. The bottom of the trench should FlexWorks primary pipe fuel oil pipe runs installed in FlexWorks corrugated Access Pipe. Retractable systems utilize Access Pipe to allow the pripling Machine). 2 Technical Data TD E Effective April 2017 Generator sizing guide fuel pipe sizing, liquid propane tank sizing, and UPSgenerator compatibility. The worksheet pages (for liquid propane or diesel tanks), sound and exhaust emissions. Oil pipe pressure drops in pounds per square inch (psi) per 100 ft pipe are indicated in the diagrams below. Oil viscosity is ranging 100 600 Saybolt Universal Seconds. 22 to 1, 650 cSt 100 to 7, 500 SSU in the normal handling range of 38 to 120C 100 to 250F. Designing a system to handle either liquid presents problems in sizing the suction link, fittings, and strainer. If calculations indicate a need for a larger pipe, lower the capacity requirements, reduce the lift, shorten. This guide applies to pipe work systems supplying kerosene to oil fired equipment under 45kW output serving single family dwellings. 1 Foot of Lift of Diesel is equal to. 886 of Hg Restriction One 90 Degree Fitting is equal to 7' of Hose Run 2 FtSec Flow may be to high and cause high restriction in some systems, and lead to a short Primary Filter Life. Fuel restriction of 4 Hg ) FUEL LINE AND PIPE RESTRICTION. Diesel Oil Pipe Sizing Guide Ebook Diesel Oil Pipe Sizing Guide currently available at for review only, if you need complete ebook Diesel Pump Sizing does the hydraulic calculation for a centrifugal pump and estimates differential head, hydraulic power, motor power, NPSH available. The methods of designing pipe systems in this booklet cover the mapress pressfitting systems for installing water supply, heating, extra light fuel oil, gas and liquefied gas systems. Each application has its own method, which reflects the different properties of the fluids carried. NFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and Components If the static head with a vent pipe filled with oil exceeds 10 psig (gage pressure of 70 kPa), the tank shall be designed to withstand the maximum static head that will be imposed. Piping Design, Treatment and Installation Fuel, lubricating oil, fresh water and compressed air piping is usually made in seamless carbon steel (DIN 2448) and seamless precision tubes in carbon or stainless steel (DIN 2391), exhaust gas piping in welded Compressed air pipe sizing has to be calculated project specifically. cotton external braided rubber fuel pipe petrol diesel line oil hose. SUITABLE FOR USE WITH FUEL INJECTION PETROL OIL DIESEL CAR. Manufactured.